Vertical Visions: Selecting And Specifying Curtain Wall Systems

As reviewed earlier in this post, various other crucial factors to consider referring to polishing option include handling solar heat gain, glare control, thermal insulation efficiency, and acoustic residential properties. The integration of sophisticated technologies like 3D printing and digital fabrication is transforming drape wall systems. These approaches enable accuracy in design and customization that were previously unattainable.

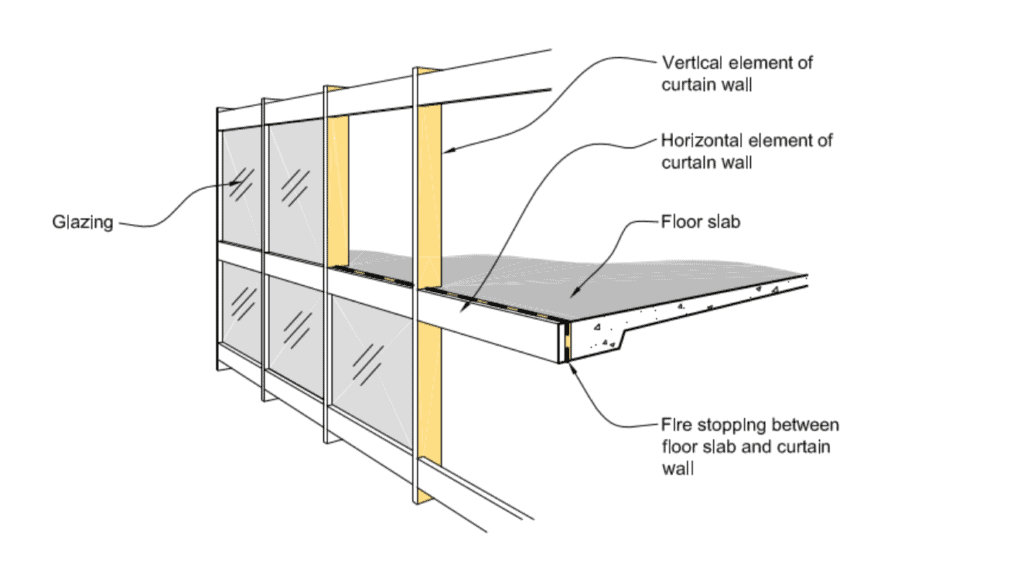

- Factory applied fluoropolymer thermoset coverings have excellent resistance to environmental deterioration and require only periodic cleaning.Curtain walls can be used for several floors and boost the outside look of the structures.Transoms are straight bars or light beams that attach the vertical members of the drape wall surfaces and offer assistance for glass and various other infill products.Drape walls are a sort of building construction that is made use of to divide the indoor space from the outside room.

What Is A Curtain Wall Surface System's Aesthetic Imprint?

Structure specifications set deflection limitations for vertical (wind-induced) and in-plane (dead load-induced) deflections. These deflection restrictions are not enforced due to strength capacities of the mullions. Rather, they are developed to restrict deflection of the glass (which may break under too much deflection), and to make certain that the glass does not appeared of its pocket in the mullion.

Terracotta panels are made from natural clay, which is a lasting and eco-friendly material. These panels are generally offered in a series of colors and coatings, giving designers and developers with higher flexibility in their layout options. Natural rock is a renewable energy that is sourced from quarries worldwide. By using in your area sourced rock and decreasing waste during the setup procedure, these systems can help to reduce their environmental effect and add to a more lasting built atmosphere. This is achieved via a combination of key and additional prevention actions. Another benefit of curtain walls is their air impermeability which helps to lower carbon dioxide discharges and energy consumption.

Architectural Analysis And Style Of Household Buildings Making Use Of Staadpro, Orion, And Hands-on Computations

Additionally, aluminium sheeting with a silicone polyester layer can be employed. By integrating these confrontings with protecting materials like EPS, rockwool, polyurethane, or polyisocyanurate, light-weight infill panels accomplishing U-values listed below 0.35 W/m ² K can be generated. As laws end up being more stringent regarding building sustainability, incorporating these innovative http://elliottqesf582.iamarrows.com/the-importance-of-appropriate-roofing-installment patterns guarantees conformity with future criteria. Building styles that take on these technologies not only satisfy present requirements yet are additionally prepared for advancing guidelines.

They're most common in small buildings with low called for quantities, yet intricate problems. Steel framing is making a little a comeback for glazed drape wall surfaces many thanks to advancements in material grades and forming innovation. While steel is naturally heavy, the appropriate system can support bigger wind and glass lots. In the stick curtain wall surface system, the components will certainly be put together piece by piece on the building and construction site itself.

Understanding Curtain Wall Surfaces: What They Are And Why They're Important For Contemporary Buildings

Drape wall supports must be developed to allow differential activity between the building structure and the curtain wall surface. A curtain wall system have to be designed to manage all tons troubled it as well as maintain air and water from penetrating the structure envelope. Typically encountered in high-rise buildings that are multiple floorings high, curtain walls are an interesting possession in modern-day design. Overall, routine maintenance and timely fixings are vital to ensure the longevity and performance of drape wall systems.

Due to the fact that they can be installed in any dimension and design, you can produce unique and aesthetically stunning exteriors. In part as a result of the adaptability of the system, curtain wall surfaces are an attractive modern-looking option for you any building exterior. Another benefit of the drape wall surface system is that it can be set up in tiny or big devices, relying on the requirements and choice for your task. The wall surfaces might cover the range of the flooring to ceiling or be mounted throughout several floorings. Acoustic waves can create a great deal of issues in buildings and also potentially lead to hearing loss; this is why drape wall surfaces are usually utilized to decrease the transmission of sound via the exteriors.